What are the testing requirements for RCDs

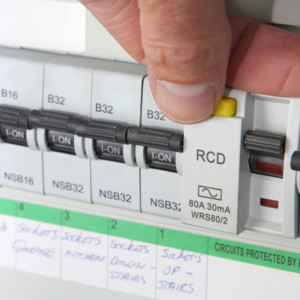

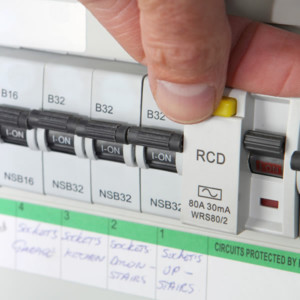

Residual Current Devices (RCDs) – also known as “safety switches” – are an important safety device that provide protection against electric shock.

RCDs are designed to protect people from electric shock whereas circuit breakers are designed to detect overload situations and protect the building and/or the appliance.

RCDs are typically found in the main switch-board of buildings and homes. Many manufacturers now incorporate RCDs into extension leads, power-boards or hand held appliances.

Portable RCDs are also available that plug directly into a power outlet. Many generators have RCDs incorporated into the power outlets.

As part of your electrical appliance safety program, ALL the RCDs used in your workplace MUST be tested regularly to ensure they are working correctly. The reason they need regular testing is dust, grit, lack of use or physical damage can cause the internal components to fail or the moving parts to “stick”, slow down or prevent it from tripping at all! You don’t want that happen.

The Standard AS/NZS 3760 sets out the maximum tripping time for a Type II RCD shall not be greater than 300 ms. That’s 0.300 of a second and is actually faster than you can blink!

There are two tests that need to be regularly performed;

The “push button” test is designed to provide an indication the RCD is working; you simply push the “test button” and the RCD should trip “without undue delay”. This quick and simple test is commonly used with portable RCDs and should be performed daily or before each time you use the RCD – which ever is the longer. However it is not particularly accurate and should never be relied on as a reliable assessment of the RCD working correctly.

The “trip time” test using the “applied current” method is a far more accurate means of testing RCDs and is a required test under AS/NZS 3760. It measures the actual trip time and must be performed with equipment able to measure this to within +/- 8 ms ( 0.008 of a second ).

The Standard also sets out the intervals to retest the RCDs under various uses and environments. For commercial cleaning use it’s every 6 months, workshops and the like every 12 months, residential facilities and low risk environments every 2 years. ( see Table 4 AS/NZS 3760 )

Don’t forget the RCD on your generator; it must be tested on a regular basis as well.

What about RCDs used by builders and tradepersons or on construction and demolition sites ( Victoria )?

Specific regulations and requirements apply to the use of RCDs on construction and demolition sites. These not only cover portable devices, but also those used in the temporary power supply box, transportable structures etc. ( see AS/NZS 3012 )

Portable RCDs, such as those incoporated in powerboards, must be “trip time” tested every three months.

However, the Industry Standard for Electrical Installations on Construction Sites (March 2002) leaves some ambiguity about the requirements; Section 4.4 states;

All portable RCDs shall be tested before each use by operation of the test button.

All RCDs should be tested for tripping current and time by a licensed electrician each calendar month while being used on the site.

The issue is through the use of the word “should” which is used to indicate recommended safe practices and procedures. Should means it is not mandatory and you have other options such as using a “competent person”, as defined under AS/NZS 3760 (and 3012), who knows how to correctly perform the required testing procedures.

That said, when in doubt, always adopt the best practice.

Learn how to correctly inspect and test RCDs with our Online Test and Tag Course.

Originally published as RCD Testing Requirements