Which Earth Continuity Test?

The earth continuity test is a designed to test the resistance of the protective earth of an appliance and/or the supply lead. It is measured between any accessible earthed parts and the earth pin of the plug.

The test is based on the principles of Ohm’s Law.

By applying a known voltage and current, the resistance can be calculated using the formula Voltage ÷ Amps = Resistance ( Ω ).

When performing the earth continuity test you have three options for the test current you apply.

- 12 V maximum, test current in the range 100 to 200 mA; commonly known as “screen test”

- 12 V maximum, test current of 10 A ( rarely used )

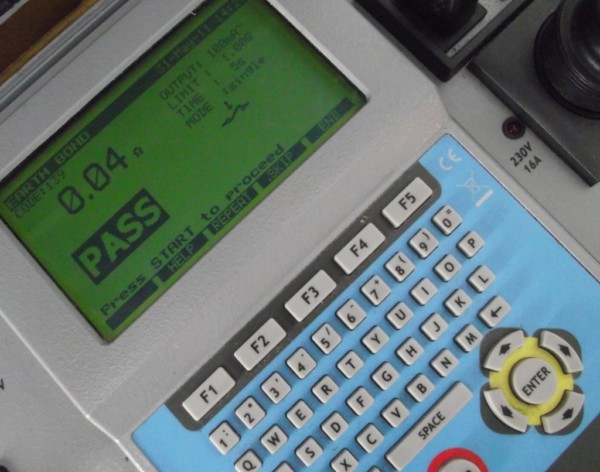

- 12 V maximum, test current of 1.5 times the rated current of the appliance or 25 A, whichever is the greater; commonly known as a “bond test”

Most portable appliance testers (PATs), including multimeters, should be able to perform the screen test. The screen test is useful for detecting poor connections of the earth conductor to either the chassis or the earth pin of the plug, commonly due to a loose connection or corrosion; the low current being applied makes it fairly sensitive to increases in resistance.

The bond test is useful for detecting defects such as breaks in the strands of the earth conductor or connections that can’t handle the maximum potential current load that could go through the earth conductor; the higher current being applied would result in high resistance reading.

When there is resistance to the current flow the energy is converted into heat. The heat may be great enough to cause the filaments to melt. Here are two examples to demonstrate how you could have a situation where performing one type of test could produce a pass and the other test would produce a fail.

Example 1 The earth connection to the chassis of the appliance is corroded. This could inhibit the flow of the low test current used with the screen test and result in high resistance readings. However the test current used in the bond test is significantly higher and it could “ram through” like a Mac truck with little resistance. In this case, the screen test would be the best choice as it would detect the defect.

Example 2 The connection to the earth pin is held in place by only a few strands. The screen test would produce a pass as there are enough strands to allow the current to flow with little resistance, however there are not enough strands for the higher test current of the bond test to flow unimpeded. This resistance could cause the strands to get so hot they melt and produce a very high resistance reading. In this case, the bond test would be the best choice.

Summary As you can see from these two common examples neither test can detect all possible earthing defects, each test has their own pros and cons.

So which should you use? Unfortunately there is no right or wrong answer. You may in fact want to perform both. Don’t be too concerned about performing the bond test on IT equipment. I have done thousands of these without any damage occurring to the appliance(s) and believe it doesn’t pose a risk to the appliance provided you do it correctly.

Further reading: Standard AS/NZS 3760 Appendix D

Learn How To Test and Tag – In-Service Inspection and Safety Inspection of Electrical Appliances And Cord Sets to AS/NZS 3760 Click here>> Test Tag Courses